How 3D Printing is Transforming Medical Diagnostics in 2025

In 2025, 3D printing is reshaping medical diagnostics by delivering unmatched precision and customization. This technology allows healthcare professionals to create patient-specific models and tools that improve diagnostic accuracy. For instance, studies show that using 3D printed prostate cancer models during robotic-assisted surgeries reduces positive surgical margins from 28.6% to 8.11%. Surgeons also report shorter operating times and better anatomical understanding. These advancements highlight how 3D printing is transforming medical diagnostics, enabling better outcomes and boosting confidence in complex procedures. You can now witness a new era of innovation in healthcare.

Key Takeaways

3D printing helps doctors by making models for each patient.

These models make tests more accurate and improve results.

Surgeons using 3D-printed models can finish surgeries faster.

On average, surgeries are 62 minutes shorter, saving money.

Custom tools made with 3D printing make procedures more exact.

This lowers mistakes and makes care better for patients.

Bioprinting is helping create working organs for people in need.

It solves organ shortages and improves research methods.

3D printing makes healthcare cheaper and easier to get for all.

Personalized medical devices are now more affordable for everyone.

Understanding How 3D Printing is Transforming Medical Diagnostics

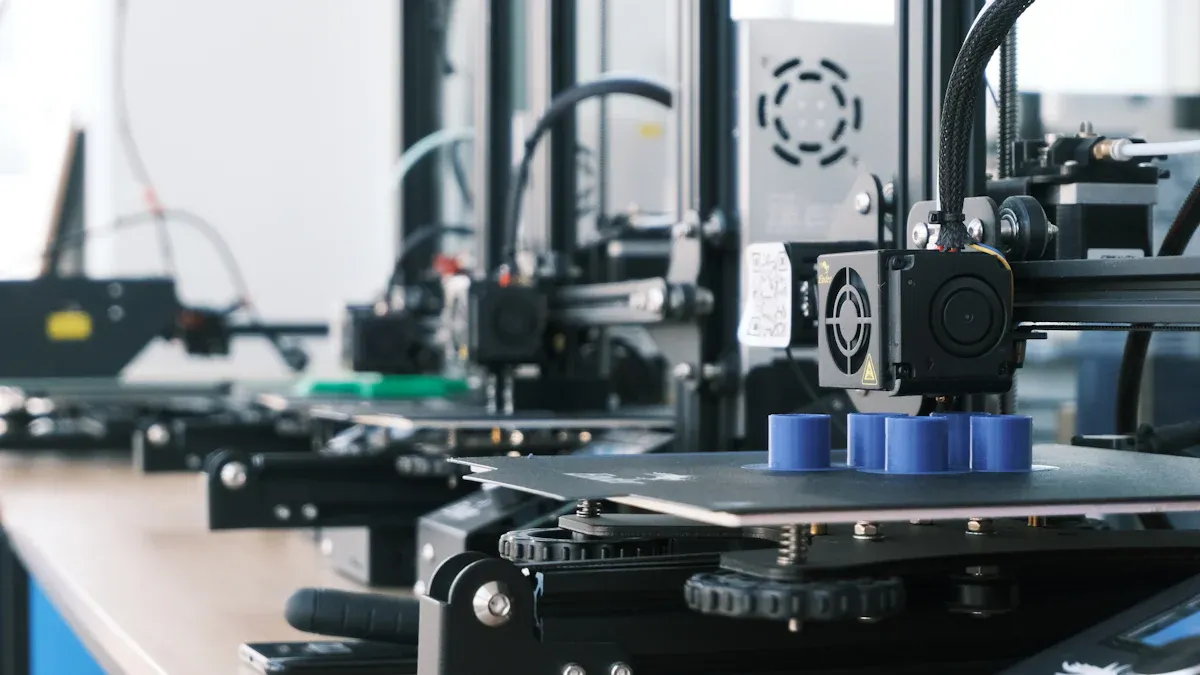

The Basics of 3D Printing Technology

3D printing, also known as additive manufacturing, builds objects layer by layer from a digital model. The process begins with creating a design using CAD (Computer-Aided Design) software. Once the design is ready, you convert it into an STL file format and transfer it to the printer's control system. The printer then uses materials like plastics, metals, or even biological substances to construct the object. After printing, you may need to perform additional steps, such as cleaning or assembling parts.

This technology has gained traction across industries, including healthcare. In fact, 66.7% of manufacturers already use 3D printing, while 24.7% plan to adopt it soon. In medicine, it enables the creation of customized implants, prosthetics, and even bioprinted tissues. By 2025, its role in diagnostics has become indispensable.

Why 3D Printing Matters in Medical Diagnostics

You might wonder why 3D printing is so crucial in diagnostics. This technology allows healthcare professionals to create precise replicas of organs and body parts. These models provide insights that traditional imaging methods cannot replicate. For example, surgeons can rehearse complex procedures using patient-specific anatomical models. This reduces the risk of errors and improves surgical outcomes.

Additionally, 3D printing enables the production of customized diagnostic tools. These tools cater to individual patient needs, enhancing the accuracy of diagnoses. Whether it's a replica of a heart for pre-surgical planning or a specialized instrument for a rare condition, 3D printing delivers solutions that were once unimaginable.

Key Benefits for Healthcare Professionals and Patients

The benefits of 3D printing extend to both healthcare providers and patients. For professionals, it offers tools that improve precision and efficiency. Customized implants and surgical instruments enhance surgical accuracy. Anatomical models help reduce operation times by aiding in pre-surgical planning. These advancements not only save time but also boost confidence in handling complex cases.

For patients, the impact is equally significant. Personalized models and tools lead to better outcomes and faster recovery times. Imagine a surgeon practicing on a 3D-printed replica of your organ before the actual procedure. This level of preparation minimizes risks and ensures a higher success rate. By 2025, 3D printing has truly transformed medical diagnostics, making healthcare more effective and patient-centered.

Current Applications of 3D Printing in Medical Diagnostics

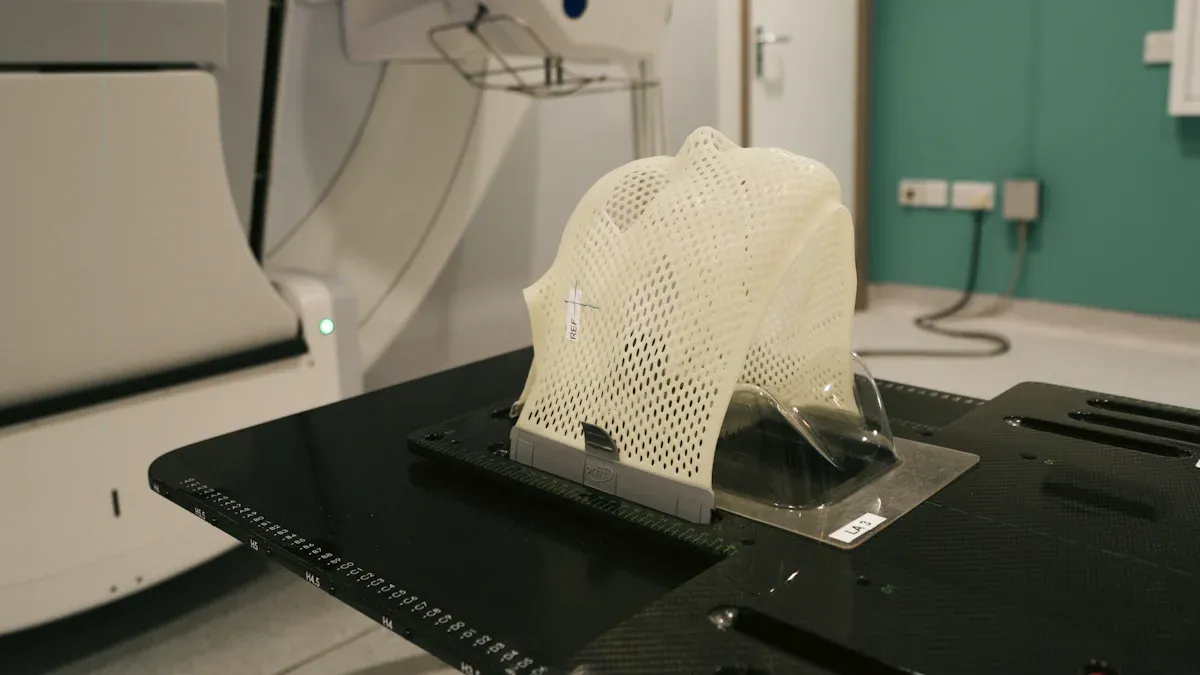

Anatomical Models for Enhanced Surgical Planning

3D printing has revolutionized surgical planning by enabling the creation of highly accurate anatomical models. These models replicate patient-specific organs and structures, allowing surgeons to visualize and rehearse complex procedures before entering the operating room. Studies show that using 3D-printed models reduces surgery time by an average of 62 minutes, saving approximately $3,720 per case. This not only lowers costs but also minimizes risks during surgery.

A literature review of 56 articles highlights the significant benefits of these models. Surgeons report reduced blood loss, shorter operating times, and lower overall costs. For example, Rady Children’s Hospital uses 3D-printed heart models to plan cardiac surgeries. These models improve patient outcomes and enhance communication between medical teams and patients.

Tip: If you or a loved one faces a complex surgery, ask your healthcare provider about the use of 3D-printed anatomical models.

Custom Diagnostic Tools for Precision Medicine

Custom diagnostic tools created through 3D printing are transforming precision medicine. These tools are tailored to individual patient needs, improving diagnostic accuracy and efficiency. For instance, 3D-printed surgical instruments like forceps and clamps are designed for specific procedures, enhancing precision and reducing errors.

Recent data demonstrates the effectiveness of these tools:

Metric | Value |

|---|---|

Sensitivity | 100% |

Specificity | 71% |

Increase in True Positives | 33% |

Cost Savings | $54,900 |

These advancements highlight how 3D printing is transforming medical diagnostics by enabling more accurate and cost-effective solutions.

Bioprinting for Organ and Tissue Research

Bioprinting, a specialized form of 3D printing, is advancing organ and tissue research. Scientists use this technology to create realistic tissue models for drug testing, reducing the need for animal trials. These models improve the accuracy of drug testing and support ethical research practices.

Evidence Description | Impact on Organ and Tissue Research |

|---|---|

Bioprinting is used to create realistic tissue models for drug testing. | Reduces the need for animal trials and enhances the accuracy of drug testing. |

Scientists are printing complex tissue structures rapidly. | Advances research in organ regeneration and transplantation significantly. |

Development of advanced bioreactor systems improves tissue maturation. | Creates optimal conditions for cell growth, leading to bio-printed organs that closely resemble natural ones. |

3D bio-printed tissues improve drug testing accuracy and ethics. | Reduces dependence on animal testing and supports successful drug screening and toxicity assessments. |

Advances in cartilage and bone regeneration technology benefit orthopedics. | Results in improved healing times and quality of life for patients undergoing reconstructive procedures. |

Bioprinting also plays a critical role in regenerative medicine. Scientists are now closer than ever to creating functional organs for transplantation. This breakthrough could address organ shortages and save countless lives.

Personalized Prosthetics and Implants

Personalized prosthetics and implants are changing lives by offering solutions tailored to individual needs. These innovations use 3D printing to create devices that fit perfectly, improving comfort and functionality. You no longer have to settle for generic designs that may not suit your body. Instead, 3D printing allows healthcare providers to design prosthetics and implants that match your unique anatomy.

Advanced imaging techniques play a key role in this process. They provide precise measurements for implant planning, reducing complications and improving success rates. Materials used in these devices are stronger and more biocompatible, ensuring durability and minimizing the risk of rejection. Surface modifications enhance bonding between implants and bones, speeding up recovery and improving long-term outcomes.

Innovation Type | Impact on Recovery Rates |

|---|---|

Enhanced digital imaging | Provides precise implant planning, reducing complications and improving success rates. |

Advanced implant materials | Improves strength and biocompatibility, leading to better long-term outcomes and reduced implant failure risk. |

Surface modifications | Enhances osseointegration, promoting faster bonding between implant and bone, improving success rates. |

Immediate loading implants | Reduces treatment time and improves patient satisfaction without compromising success rates. |

Bone grafting and regeneration | Improves support for implants in patients with insufficient bone volume, enabling more successful outcomes. |

Smart implants | Monitors implant performance in real-time, allowing for early detection of issues and timely interventions. |

Personalized treatment plans | Tailors treatment to individual biological profiles, improving predictability and success rates. |

Smart implants take personalization even further. These devices monitor performance in real time, allowing for early detection of issues. You benefit from timely interventions that prevent complications. Immediate loading implants also reduce treatment time, giving you faster results without sacrificing quality.

By 2025, personalized prosthetics and implants have become essential in medical diagnostics. They improve recovery rates, enhance patient satisfaction, and offer solutions that were once unimaginable. You can now experience healthcare that truly understands your needs.

Advancements in 3D Printing Expected by 2025

Integration with Artificial Intelligence for Smarter Diagnostics

Artificial Intelligence (AI) is revolutionizing how 3D printing enhances medical diagnostics. By 2025, AI integration is expected to make diagnostics faster and more accurate. AI-powered tools analyze complex data, helping clinicians identify patterns and predict health outcomes. For example, AI can optimize 3D-printed diagnostic devices, ensuring they meet specific patient needs. This combination of AI and 3D printing supports personalized medicine, enabling tailored treatments for individual patients.

The future of 3D printing in medical devices also includes AI-driven automation. This innovation streamlines production processes, reducing errors and improving efficiency. Imagine a scenario where AI designs a 3D-printed implant with unmatched precision. Such advancements will redefine how you experience healthcare, offering smarter and more reliable diagnostic solutions.

Innovations in Bioprinting and Tissue Engineering

Bioprinting is advancing rapidly, with groundbreaking innovations expected by 2025. AI-driven bioinks are transforming drug discovery and regenerative medicine. These bioinks allow scientists to create realistic tissue models, improving the accuracy of drug testing. Scaffold-free printing techniques are another game-changer. They enable the self-assembly of functional tissues, bringing researchers closer to creating fully functional organs.

Advanced bioreactor systems are also improving tissue maturation. These systems provide optimal conditions for cell growth, ensuring bio-printed tissues closely resemble natural ones. AI plays a crucial role here as well. It optimizes cell placement and monitors the quality of bio-printed constructs in real time. These innovations will make tissue engineering more precise and efficient, paving the way for life-saving breakthroughs.

Cost-Effective Solutions for Broader Accessibility

3D printing is becoming more affordable, making advanced medical solutions accessible to a wider audience. By 2025, cost-effective methods will significantly reduce expenses for patients and healthcare providers. For instance, 3D-printed prosthetics cost as little as $50 to $100, compared to traditional prosthetics priced between $1,500 and $8,000. This affordability ensures that more people can benefit from personalized medical devices.

Application | Traditional Cost | 3D Printing Cost | Time Savings |

|---|---|---|---|

Prosthetics | $1,500 - $8,000 | $50 - $100 | N/A |

Surgical Planning | N/A | N/A | Reduces surgery time by 62 minutes, saving $3,720 per case |

Medical Devices | N/A | N/A | Over 90% of top 50 companies use 3D printing for prototyping and production |

These advancements align with sustainability goals by reducing material waste and production costs. As a result, 3D printing is not only transforming medical diagnostics but also democratizing access to cutting-edge healthcare solutions.

New Materials and Techniques for Greater Accuracy

Advances in materials and techniques are pushing the boundaries of 3D printing in medical diagnostics. By 2025, you’ll see innovations that deliver greater precision and reliability, making healthcare more effective than ever.

Cutting-Edge Materials

New materials are transforming the capabilities of 3D printing. Biocompatible polymers, such as polyether ether ketone (PEEK), offer durability and compatibility with the human body. These materials reduce the risk of rejection and improve the longevity of implants. Metal alloys, including titanium and cobalt-chromium, provide strength for surgical tools and prosthetics. You’ll also encounter bioinks made from living cells, which enable the creation of functional tissues for research and regenerative medicine.

Note: Bioinks are essential for bioprinting. They mimic the properties of natural tissues, ensuring realistic results in organ and tissue models.

Innovative Techniques

New printing methods are enhancing accuracy. Multi-material printing allows you to combine different substances in a single model, creating complex structures that closely resemble natural anatomy. High-resolution printers now achieve layer thicknesses as small as 10 microns, ensuring intricate details in diagnostic tools. Techniques like stereolithography (SLA) use lasers to cure resin, producing smooth and precise surfaces ideal for surgical planning.

Technique | Key Benefit |

|---|---|

Multi-material printing | Combines materials for complex models |

High-resolution printing | Captures fine details for accuracy |

Stereolithography (SLA) | Produces smooth surfaces |

These advancements make diagnostics more reliable. You’ll benefit from tools that improve surgical outcomes and reduce errors. With new materials and techniques, 3D printing continues to redefine what’s possible in healthcare.

Challenges in 3D Printing and How They Are Being Overcome

Navigating Regulatory Hurdles

Regulatory challenges often complicate the adoption of 3D printing in medical diagnostics. You may notice that oversight responsibilities can become unclear, especially when hospitals use 3D printers to create patient-specific devices. Regulatory bodies like the FDA and Singapore’s health authorities focus on biocompatibility testing, clinical studies, and risk categorization to ensure safety. However, these processes can be time-consuming and costly.

Aspect | Details |

|---|---|

Regulatory Bodies | FDA, Health Authorities in Singapore |

Key Focus Areas | Biocompatibility testing, Clinical studies, Risk categorization |

Testing Requirements | In-depth reports, worst-case scenario analysis, adherence to regulations |

Biocompatibility Evidence | Must be device-specific; prior evidence is inadequate |

Efforts to address these hurdles include proactive discussions by the FDA to clarify frameworks and gather feedback from stakeholders. Medical societies are also working to implement reimbursement processes, which could lead to permanent reimbursement codes for 3D-printed devices.

Addressing High Costs and Resource Limitations

The high cost of 3D printing technology remains a significant barrier. Hospitals often bear the financial burden of implementing 3D printing programs without insurance reimbursement. Additionally, the limited range of biocompatible materials and precision challenges in creating complex biological structures hinder broader adoption.

Medical device manufacturers increasingly use 3D printing to reduce costs and meet supply demands.

Decentralized manufacturing raises quality control issues, impacting the consistency of 3D-printed devices.

Regulatory oversight focuses on final medical devices but not the printers, creating ambiguity.

Despite these challenges, advancements in materials and techniques are making 3D printing more affordable. For example, 3D-printed prosthetics cost as little as $50, compared to traditional options priced at thousands of dollars. These cost-effective solutions are paving the way for broader accessibility.

Ethical Considerations in Bioprinting

Bioprinting introduces complex ethical questions. Ownership rights of bioprinted organs remain unclear. Should the patient, manufacturer, or medical institution hold these rights? Additionally, the high costs of bioprinting technologies may limit access, creating disparities in healthcare.

Note: Equitable access to bioprinting technologies is essential to prevent widening the gap in healthcare availability.

Addressing these concerns requires collaboration among policymakers, healthcare providers, and manufacturers. By prioritizing transparency and equity, you can ensure that bioprinting benefits everyone, not just a privileged few.

Overcoming Technical Barriers in Complex Applications

3D printing in medical diagnostics has faced significant technical challenges, especially in complex applications. However, recent advancements have addressed many of these barriers, making the technology more reliable and effective for healthcare professionals like you.

One major breakthrough involves bioprinting. Engineers have developed custom extrusion heads that allow for multi-material designs. This innovation improves precision and enables the creation of complex tissue structures. You can now rely on bioprinting for more accurate organ and tissue models, which are essential for research and regenerative medicine.

Another area of progress is anatomical modeling. Advanced imaging techniques now convert patient-specific data into highly detailed 3D models. These models enhance surgical planning and medical education. For example, surgeons can practice on a replica of your organ before performing a procedure. This preparation reduces risks and improves outcomes.

Personalized medication has also seen remarkable improvements. 3D printing now produces custom dosage forms and unique drug delivery systems. These innovations ensure that treatments are tailored to your specific needs, enhancing their effectiveness.

Evidence Type | Description |

|---|---|

Bioprinting Innovations | Development of custom extrusion heads for multi-material designs, enhancing precision in bioprinting. |

Anatomical Modeling | Creation of patient-specific models from imaging data, improving surgical planning and education. |

Personalized Medication | Production of custom dosage forms and unique drug delivery systems, enhancing treatment outcomes. |

Tip: If you're considering a complex medical procedure, ask your doctor about the use of 3D-printed tools or models. These advancements could significantly improve your care.

By overcoming these technical barriers, 3D printing has become a powerful tool in medical diagnostics. It offers solutions that were once impossible, ensuring better outcomes for both you and your healthcare provider.

The Future of 3D Printing in Medical Diagnostics

Transforming Patient Care Through Personalization

3D printing is revolutionizing patient care by enabling unmatched levels of personalization. You can now benefit from medical devices and tools tailored specifically to your anatomy and needs. For instance, personalized prosthetics and implants created through 3D printing improve comfort and functionality. These solutions are especially impactful in underserved areas, where traditional manufacturing methods often fall short.

Custom surgical instruments also enhance precision during procedures. Surgeons using these tools report significant time savings and better outcomes. For example, Dr. Michael Eames reduced surgery time from 3 hours to less than 30 minutes by utilizing a 3D-printed model, saving $5,500 per procedure. This level of customization ensures that your care is not only effective but also efficient.

Evidence Type | Details |

|---|---|

Surgery Time Reduction | Average reduction of 62 minutes per surgery, saving approximately $3,720 per case. |

Personalized Prosthetics | Highly customized solutions that improve accessibility for patients, especially in underserved areas. |

Reducing Diagnostic and Treatment Times

3D printing is also helping to reduce the time it takes to diagnose and treat medical conditions. Surgeons using 3D-printed anatomical models can rehearse procedures in advance, cutting operating times by up to 20%. These models save an average of 62 minutes per surgery, translating to cost savings of $3,720 per case.

In some cases, the time savings are even more dramatic. Dr. Michael Eames used a 3D-printed model to decrease surgery time from 3 hours to less than 30 minutes. This not only saved $5,500 but also reduced the physical strain on patients. Faster procedures mean quicker recovery times for you, making healthcare more efficient and patient-centered.

Surgeons using VR rehearsals reduced operating times by up to 20%.

3D-printed anatomical models reduce surgery time by an average of 62 minutes, saving approximately $3,720 per case.

Surgery durations shortened by 1.5 to 2.5 hours in various cases.

Democratizing Access to Advanced Medical Solutions

One of the most exciting aspects of 3D printing is its ability to democratize access to advanced medical solutions. This technology allows for the creation of cost-effective, personalized devices that were once prohibitively expensive. For example, 3D-printed prosthetics cost as little as $50 to $100, compared to traditional options priced between $1,500 and $8,000.

By minimizing material waste and reducing production costs, 3D printing makes cutting-edge healthcare accessible to more people. This is particularly beneficial in underserved areas, where resources are often limited. You can now access advanced medical solutions that were previously out of reach, ensuring equitable healthcare for all.

Customization and personalization enhance fit and function for individual patients.

Cost-effective production minimizes waste and lowers costs.

Advanced medical technology becomes more accessible, especially in underserved areas.

Trend | Description |

|---|---|

Greater Focus on Sustainability | 3D printing will help reduce waste and use fewer materials, aligning with sustainable healthcare practices. |

Democratizing Access | Lower costs make advanced medical solutions accessible to underserved areas. |

3D printing is revolutionizing healthcare by offering unmatched precision and customization. By 2025, advancements in bioprinting are addressing the global shortage of organs, enabling the creation of tissues and small organs like kidneys. Precision instruments and organ models are refining surgical techniques, leading to faster recovery and reduced operation times. Patient-specific devices are transforming care, ensuring better outcomes. How 3D Printing Is Transforming Medical Diagnostics highlights a future where innovation continues to redefine healthcare, making it more efficient and accessible for everyone.

FAQ

What is 3D printing, and how does it work in medical diagnostics?

3D printing builds objects layer by layer from a digital design. In medical diagnostics, it creates models, tools, and implants tailored to your anatomy. This process improves precision and enhances outcomes by enabling healthcare providers to plan surgeries, test drugs, and develop personalized treatments.

How does 3D printing improve surgical outcomes?

3D-printed anatomical models let surgeons practice procedures before operating. This preparation reduces errors, shortens surgery times, and improves accuracy. For example, using a 3D-printed heart model helps surgeons better understand complex structures, ensuring safer and more effective surgeries for you.

Are 3D-printed medical devices safe to use?

Yes, regulatory bodies like the FDA ensure the safety of 3D-printed medical devices. These devices undergo rigorous testing for biocompatibility and performance. You can trust that approved 3D-printed tools and implants meet strict safety standards.

Can 3D printing make healthcare more affordable?

Absolutely! 3D printing reduces production costs and material waste. For instance, prosthetics made with 3D printing cost as little as $50, compared to traditional ones priced at thousands of dollars. This affordability makes advanced medical solutions accessible to more people, including you.

What are the limitations of 3D printing in medicine?

3D printing faces challenges like high costs for advanced machines, limited biocompatible materials, and regulatory hurdles. However, ongoing innovations aim to overcome these barriers, ensuring that you benefit from safer, more effective, and widely available medical solutions.

See Also

Recognizing Duodenal Cancer Symptoms And Available Treatments

Insulinoma Explained: Its Importance And Key Information

Endodermal Sinus Tumors: Symptoms And Diagnostic Insights

Conjunctival Melanoma: Key Symptoms And Treatment Options

Key Characteristics Of Glioblastoma: A Comprehensive Overview